Most of us have been in this situation before – our painting has finally reached a point of completion, it’s dry and ready to be sent off but you’ve noticed that the surface quality is uneven – there are glossy areas in some parts of the painting and matte areas in others. Also, the darker values of the painting have lost some of their saturation and depth. This is quite common. Oil colors naturally dry to varying surface qualities, as different pigments require different amounts of oil binder. Also, using painting medium is some areas of the painting may exaggerate these variations. Perhaps the painting was done on absorbent, acrylic ground (“gesso”) which pulls oil away from subsequent paint layers. Not to worry…these issues of surface quality and color saturation can easily be remedied through the application of a final picture varnish.

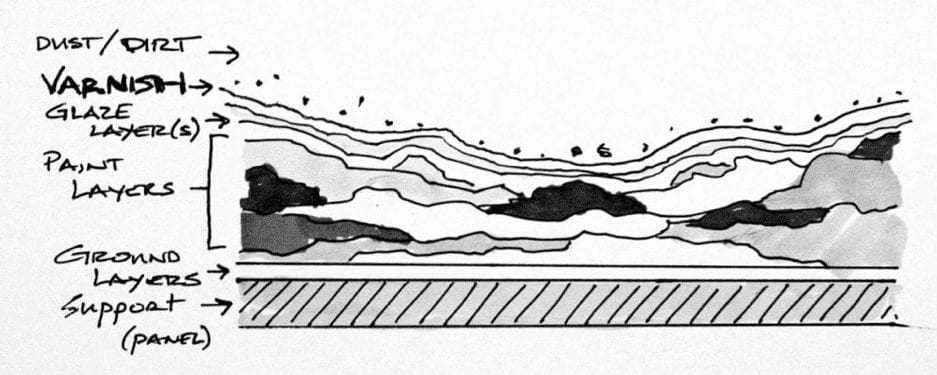

Picture varnishes address two important concerns – one in the short term and the second in the longer term. First, a varnish layer solves those immediate aesthetic concerns outlined above by achieving a uniform surface quality and, in the case of gloss varnishes, increasing the sense of depth in your finished works. Second, the varnish layer protects oil paintings from environmental dirt and dust over the life.

The information below discusses both the issue of choosing the appropriate surface quality for your work and the benefits gained by protecting your work for the long-run.

16″ x 20″ Oil on Panel zzfineart.com

It’s the easiest way to make your painting look better

As mentioned, it is common for paint layers to dry to different surface qualities. Some pigments used in oil colors require more oil and dry with more gloss, other pigments require less oil and dry matte. During the painting process, it can be beneficial to even out the surface quality to better evaluate the values of the painting and deepen the color saturation. We recommend “oiling out” the surface of the painting with a mixture of Galkyd painting medium and Gamsol for this. As the small amount of painting medium will bond permanently to previous and subsequent layers, this procedure is preferable to using retouch varnish. “Oiling out” has its benefits on a recently completed painting as well, since it not only unifies the surface quality but it reduces the absorbency of paint layers – allowing the subsequent varnish layer to remain on the top-most part of the painting structure.

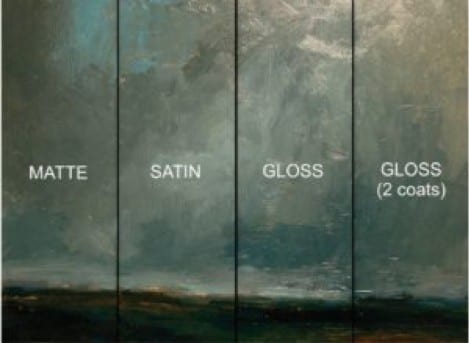

Whether you “oil out” the painting or not, varnishing is the best way of unifying the dry paint layers with the desired surface quality for your work. But what type of surface is right for the painting? High gloss? Dead matte? Something in between? Finding the appropriate surface quality is a very personal choice. Gloss surfaces beautifully saturate dry paint layers and increase the sense of depth in paintings. Matte surfaces give paint layers a very direct appearance, but can lighten the darkest values of a painting. Historically, representational painters preferred a gloss surface because of the increased sense of depth. Abstract painters adopted matte surfaces to enhance the physicality of paint layers. This, of course, is an over-generalization. What’s most important is that you find the right surface quality for your work.

The other aspect of this is how the environment affects the viewing of the work once the painting is installed. Paintings that have a gloss surface can be difficult to see if they are not lit properly. This can take away from the painted image to the point of being distracting.

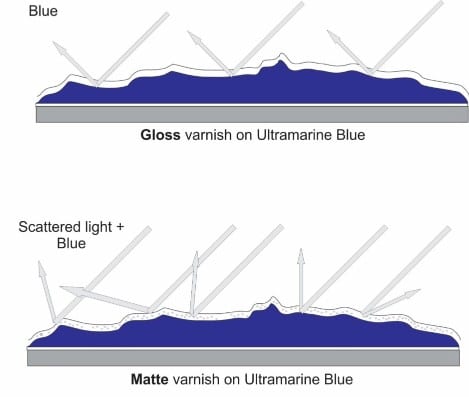

What makes for a glossy or matte surface on a painting? Gloss varnishes encourage the reflection of light in a specular, or mirror-like, direction off the surface of the painting. Gloss surfaces deepen values and saturate colors in paintings. Matte varnishes are formulated with matting agents (solids) in the varnish layer, which act to scatter the light at the surface of the painting. Depending on the amount of matting agents in the varnish layer, matte varnishes lighten the darkest values in paintings.

Varnish protects paintings

It

If and when the painting needs to be cleaned, the varnish layer can be easily removed from the painting, along with the dust and dirt that has accumulated on top. In this way, a varnish should be thought of as a discrete, “sacrificial” layer to the rest of the painting.

Contemporary varnishes

Traditional dammar varnish and other natural resins make a durable top layer but yellow and darken over time and become increasingly difficult to remove for purposes of cleaning a painting. In the mid-20th century, acrylic resin varnishes were adopted because of their stability of color. However, these same varnishes changed the look of paintings, leading many conservators back to the use of dammar, despite its tendency to yellow with age.

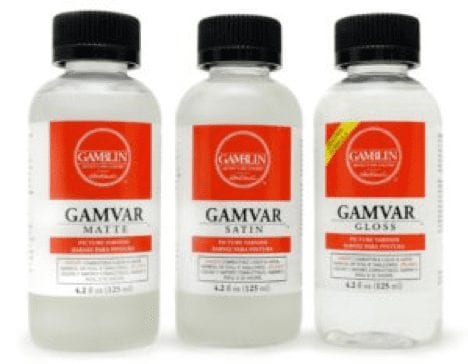

In the early 1990s, Robert Gamblin collaborated with Rene de la Rie at the National Gallery of Art in Washington, DC, to bring a contemporary varnish to the studio painter. The research that came out of the National Gallery identified the most stable resin, Regalrez 1094, to be used as a picture varnish. This resin not only beautifully saturates dry paint layers, but is also formulated into a varnish with a very mild solvent – Gamsol. Equally as important, this varnish can be removed with Gamsol, posing very little risk of damaging paint layers below.

Gamvar Picture Varnish has now been available to painters for over two decades.

When to varnish

For most paintings, there is no need to wait 6 to 12 months before varnishing with Gamvar. Gamvar can be applied when the thickest areas of your painting are thoroughly dry and firm to the touch. Gently press your fingernail into the thickest area of paint. If it is firm underneath the surface, then it is ready for varnishing.

To varnish or not to varnish?

Similar to finding the appropriate frame for a painting, applying a varnish is an excellent way of putting a finishing touch on an original work of art. Not only does a final varnish coat unify and saturate color, but it plays an invaluable role in protecting your deeply-valued painting. In short, we recommend varnishing.

Additional references

Product information: Gamvar Gloss, Gamvar Matte, Gamvar Satin